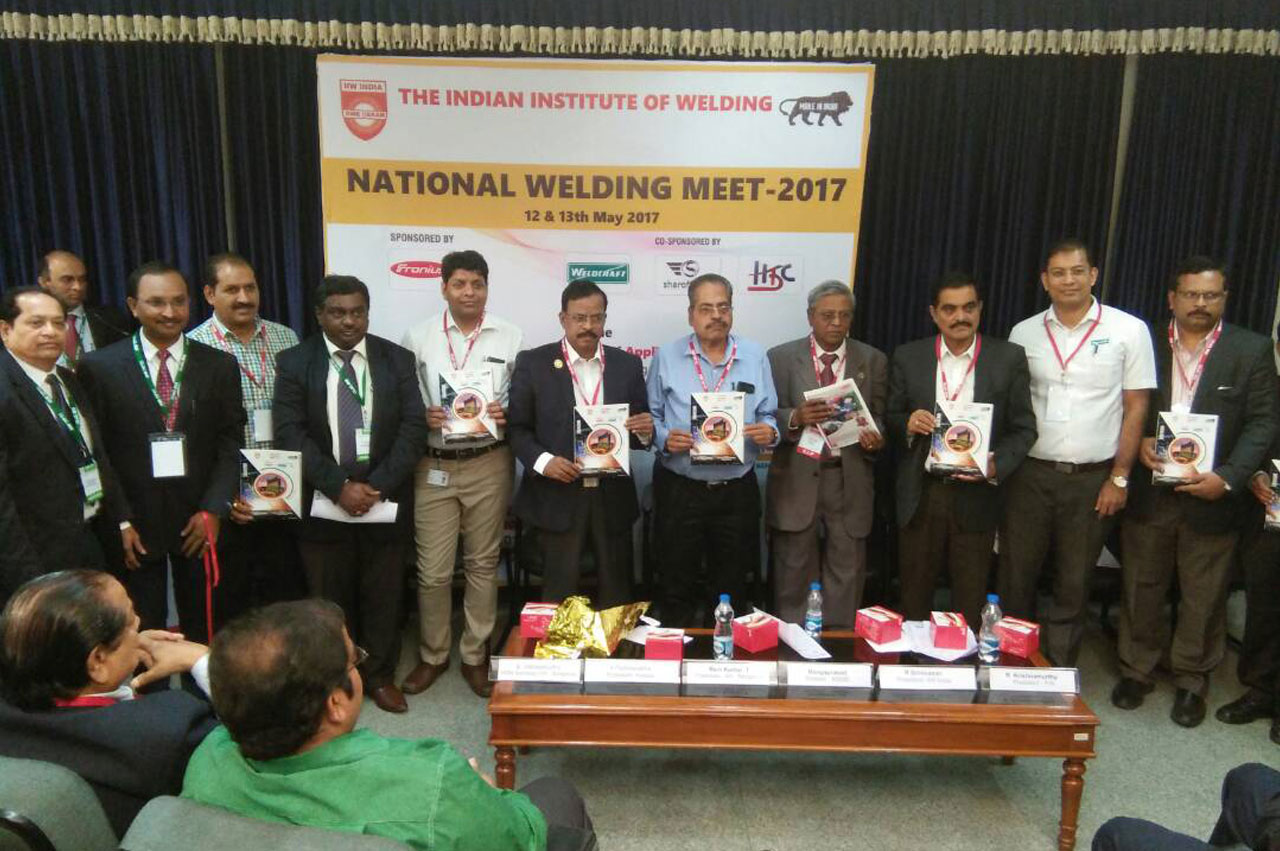

[vc_row][vc_column][vc_column_text]For fabrication industries and other industries associated with welding, the 3-day National Welding Meet (NWM) and Weld Tech Expo 2017 organized by the Indian Institute of Welding and hosted by its Bangalore Branch at Neelakanta Convention Centre, opp. BIEC, Tumakuru Road, Bengaluru was a must-visit event. The event was themed on Advances in Welding Technology and Skill Development for Make in India.

Sharing his views on the participation of some entrepreneurs in Peenya in the NWM 2017, PIA President Sri R.  Krishnamurthy said the Weld Tech Expo focused on recent developments in welding and present opportunities for welding professionals and welders to improve their skills and capabilities.

Krishnamurthy said the Weld Tech Expo focused on recent developments in welding and present opportunities for welding professionals and welders to improve their skills and capabilities.

“Today, Welding is an absolute essential component of majority of the manufacturing sector and is treated as special process across sectors ranging from Manufacturing to construction and defense to power sectors,” he said and declared that the Welding industry is poised for a vibrant change through latest developments enabling high productivity welding processes, cost-effective designs and reliable quality control methods that can play a vital role in Make in India. It is extremely important that manufacturing units keep up with the latest changes in the cutting edge, he added.

The participants from Peenya included a cross section of personnel engaged in the Welding Process Technology in general and practicing Engineers, Professionals, Faculties, Managers and Supervisors from Fabrication Industries, Research Personnel, Academicians, Students, Power & Process Plant Maintenance Personnel, Manufactures of Power Sources, Welding Consumables suppliers, Welding Equipment manufacturers, Skill development institutes on Welding etc.

Technical Papers were presented at the Expo on areas such as Advanced Welding Processes, Special Welding techniques, Welding Productivity & Quality improvement techniques, Welding Equipment manufacturing, Welding Consumables, QA/QC of welds/fabrication, Welding Inspection, Skill Development & training on Welding, modern welding practices, standardization and certification of welding workshops, cutting techniques for welding and related case studies.

The profile of Exhibitors included Welding Brazing Soldering Equipment Manufactures; Consumables, Fixtures, Welding Inspection Equipment, accessories suppliers; Advanced Welding Processes; Cutting Equipment; Fabrication/Welding Industries; Welding Automation & Robotics; Repair & Maintenance Welding; Welding Safety Equipment & Accessories; Non-destructive testing Equipment & Services; Industrial Gases Suppliers; Material Testing Labs; Raw Material Suppliers(Iron & Steel, Pipes, Tubes, Flats, Aluminium , Stainless Steel, Copper etc; Sheet Metal Fabricators; Bending & Punching Industries; Heat Treatment & Ovens Manufacturers; Laser Cutting; Crane Manufacturers & Suppliers; Structural Manufacturers; Transformer Manufacturers; Panel Board Manufacturers; Welding Machine, Consumables & Accessories & Suppliers; Heavy Fabrication Industries; Material Handling Equipments- Manufacturers & Suppliers; Aluminium Welding- Fabricators & Suppliers; Stainless Steel Welding – Fabricators & Suppliers; Steel Furniture Manufactures & Suppliers; Banks; Technical Institutions.[/vc_column_text][/vc_column][/vc_row]